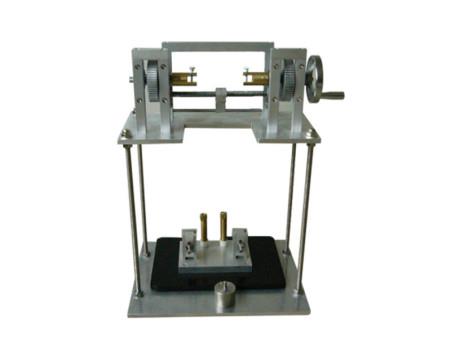

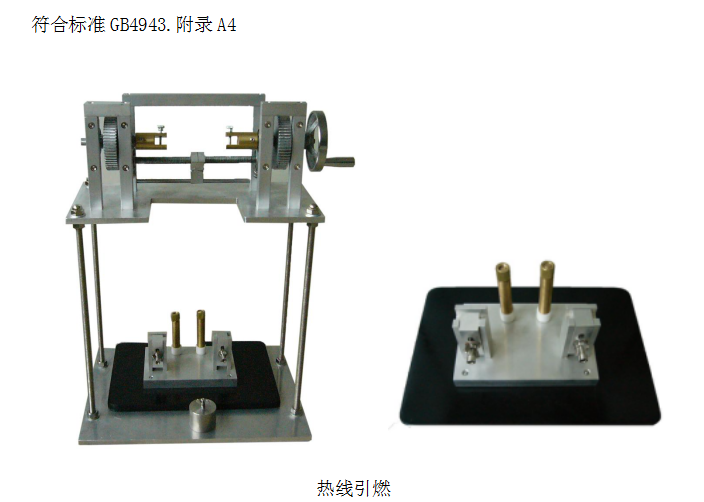

Hot wire ignition winder

Test circuit: 250mm +/- 5mm long, 0.5mm (+0.02mm, -0mm), nickel-chromium wire with a cold resistance of 5.28 ohms/meter (IEC requirement 5.25) (nominal composition is 80% nickel, chrome 20 %, without iron), connect the straight hot wire to the adjustable power supply, the power supply should be adjusted to the power consumption of 0.26W/mm +/- 4%, and keep the power for 8s-12s. After cooling, wrap it around the sample for 5 turns with a pitch of 6 mm.

Sample size: 130mm*13mm,

Test circuit: 250mm +/- 5mm long, 0.5mm (+0.02mm, -0mm), nickel-chromium wire with a cold resistance of 5.28 ohms/meter (IEC requirement 5.25) (nominal composition is 80% nickel, Chromium 20%, no iron), the straight wire is connected to the adjustable power supply, the power supply should be adjusted to the power of the wire to generate 0.26W / mm +/- 4% of the power dissipation, and maintain 8s-12s, wait After the hot wire is cooled, it is wound around the sample for 5 turns with a pitch of 6 mm.

The sample hot wire should be supported in a horizontal position. Both ends of the hot wire are connected to the adjustable power supply. The adjustable power supply can be re-adjusted to produce 0.26 W/mm +/- 4% of the dissipated power of the hot wire.

At the beginning of the test, the circuit is energized to produce a linear power density of 0.26 W/mm +/- 4% through the hot wire. The test is continued until the test sample is ignited or reaches 120 s. When the ignition occurs or has reached 120 s, the test is interrupted. And record the test time. For samples that are melted by the hot wire but still not ignited, the test can be interrupted when the sample is no longer in close contact with all 5 turns of hot wire.